Battery Labs process

Once we receive a hybrid battery we disassemble the battery down to just the modules, and then put the battery through a deep reconditioning process. The process restores capacity and load tests each Individual module to determine durability and to eliminate weak or bad modules. The state of health of each module is recorded and put into our inventory. From there we group modules with the most similar capacity and characteristics in our inventory, To ensure you the healthiest battery possible. The rest of the battery including wiring, ecu’s, and other components are then inspected and tested. We then build the battery and connect modules with new nickel plated bus bars and hardware to prevent corrosion so our customers can get the longest life out of their battery.

Warranty- we stand behind a 12 month unlimited mile warranty on all of our batteries

- Warranty will be voided if battery is removed from vehicle, tampering, or damage to warranty labels.

Installation/delivery- All batteries come with free installation. Depending on your vehicle, most will come with free delivery to your location. We will deliver up to 200 miles from our location in Richmond Kentucky.

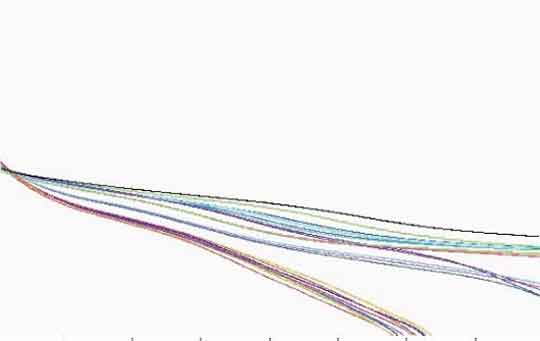

BEFORE CONDITIONING

This is the state of the battery when we receive it. This is before any work or cycling has been performed. The colored lines represent individual modules.

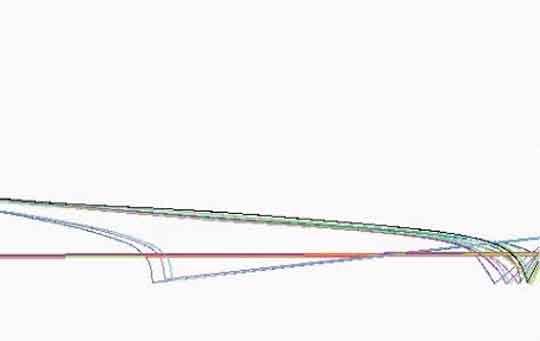

DURING CONDITIONING

This is the state of the battery during deep cycle. The deep cycle process lets us know what modules are weak, healthy and which may have a shorter life than others. From this point we profile and pick out the best modules to construct a new battery

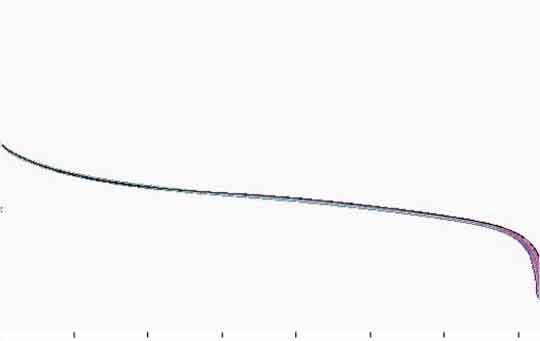

AFTER CONDITIONING

After the reconditioning process the healthy modules are paired with like modules with similar characteristic to make the longest lasting battery possible